Hosted by the Tata Steel Advanced Materials Research Centre, MaterialNEXT is an open innovation platform that aims to promote entrepreneurship and innovation in the areas of materials for various sectors such as mobility, healthcare, building materials and industrial equipment.

From IISc, a student team called “Changemakers” was announced as the first runner-up in the competition for creating prototypes of bioabsorbable and deployable biliary stents using shape memory polymer composites. The team consisting of Saswat Choudhury and Rishabh Soni was mentored by Kaushik Chatterjee, Associate Professor in the Department of Materials Engineering, IISc and Dr Sonal Asthana, clinical lead from Aster Hospital, Bangalore. They received a cash prize of Rs 2.5 lakh.

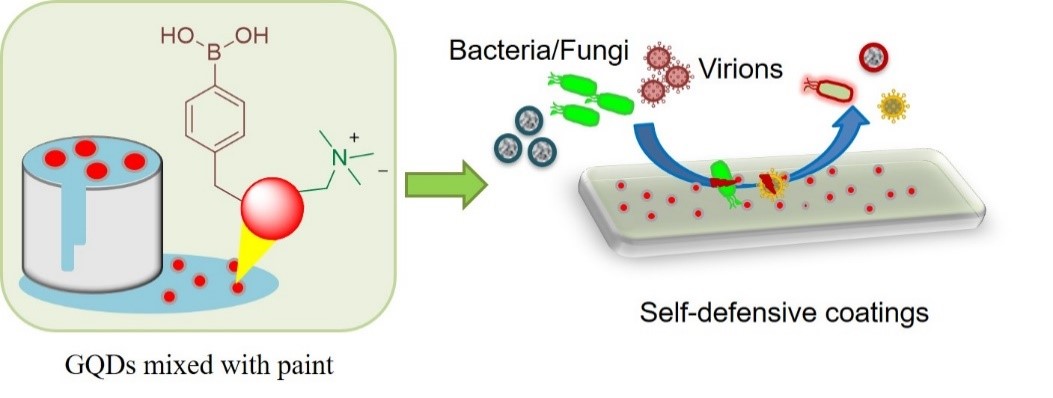

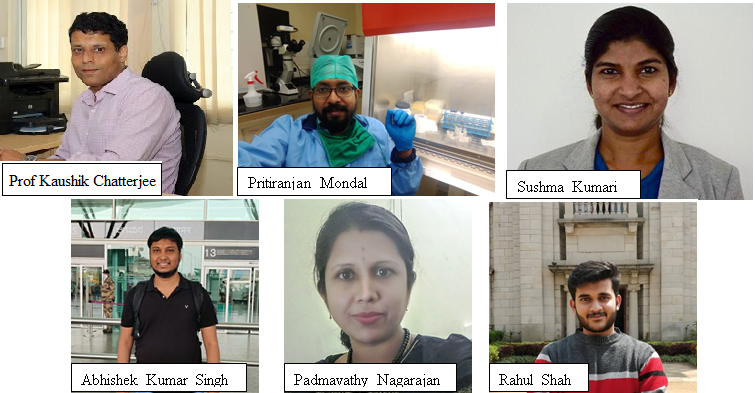

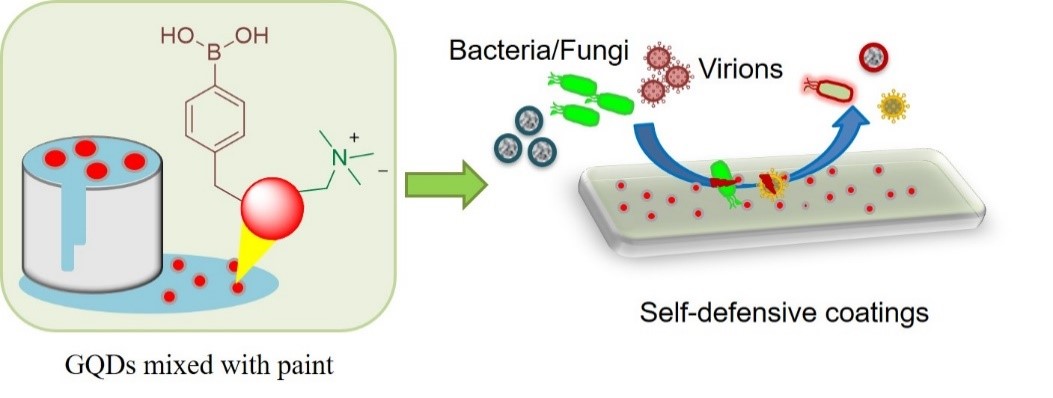

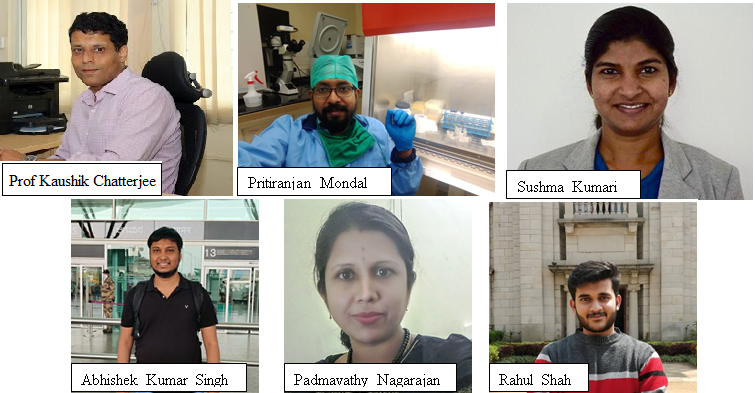

Another team from IISc called “Biomaterials” was also recognised among the top 5 and won a cash prize of Rs 1 lakh for their idea of antimicrobial paints and coatings using functionalised graphene quantum dots (GQDs). The team comprised Pritiranjan Mondal, Abhishek Kumar Singh, Rahul Shah, Sushma Kumari and Padmavathy Nagarajan, and was also mentored by Kaushik Chatterjee.

https://www.tatasteel.com/media/newsroom/press-releases/india/2021/tata-steel-announces-the-winners-of-the-second-edition-of-materialnext-programme/

Team Changemakers: We are an interdisciplinary research group based in IISc with a strong focus on biomaterials and tissue engineering for different biomedical applications. There is a huge unmet clinical need to replace existing stents and other medical devices that are non-degradable and require multiple surgical procedures to remove them. Also, the initial implantation of such medical devices requires surgery due to their bulky designs. Our approach was to have an absorbable medical device made of polyesters that also exhibited shape memory behavior. We used advanced and novel shape memory polymer composites that could undergo deformation to be implanted in a minimally invasive manner and then recover back to its original conformation at physiological temperatures upon remote actuation. Our proposal holds great promise towards clinical translation. We are excited to be the runner up in this competitive event and look forward to further exciting engagements!

Team Biomaterials: Microbial surface contamination is a major challenge in the healthcare industry, food industries, municipal infrastructure, and transportation systems. Therefore, to control the spread of infections, there is an increasing demand for exploring more effective, cost-efficient, broad-spectrum, durable, and long-standing antimicrobial formulations or coatings to self-disinfect the frequently touched surfaces. In the current project, we have synthesised GQDs and then post-functionalised them with cationic & anionic antimicrobial moiety. Next, we have mixed these chemically modified GQDs nanoparticles with commercially available paints and coated various surfaces such as metals, polymers, and ceramics. We investigated that these nanomaterials coated surfaces can maintain long-term antimicrobial activity against pathogenic microorganisms (bacteria and viruses). Therefore, these antimicrobial active GQDs can be used as an alternative, longer lasting, and more eco-friendly antimicrobial coatings. We believe that in the event of outbreaks and the current COVID-19 pandemic scenario, our antimicrobial GQDs formulated coated materials would be much helpful in preventing the transmission of infectious diseases.