4 November 2025

– Sayooj P

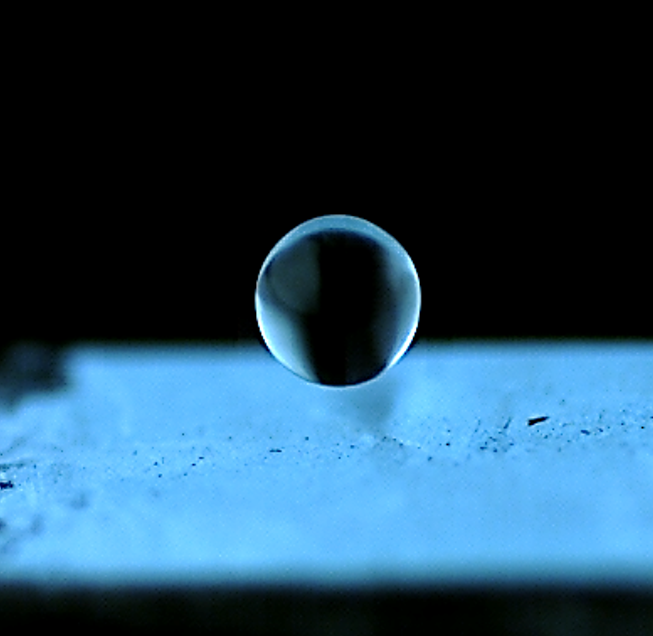

Water droplets can slide down or bounce off a leaf’s surface because it has a waxy hydrophobic (water-repellent) coating. However, this poses a challenge to farmers when pesticides are sprayed, as the droplets can bounce off plants without sticking to them, and contaminate soil and water.

“Around 50% of the pesticides are wasted this way,” says Rutvik Lathia, former PhD student at the Centre for Nano Science and Engineering (CeNSE), IISc, and currently a postdoc at the Max Planck Institute for Polymer Research.

Rutvik is part of a team led by Prosenjit Sen, Associate Professor at CeNSE, which has come up with an ingenious way to tackle this problem. The new approach uses Liquid Marbles (LMs), and is a safer alternative to using surfactants, polymers, and oils – which are harmful to the environment – to increase wettability.

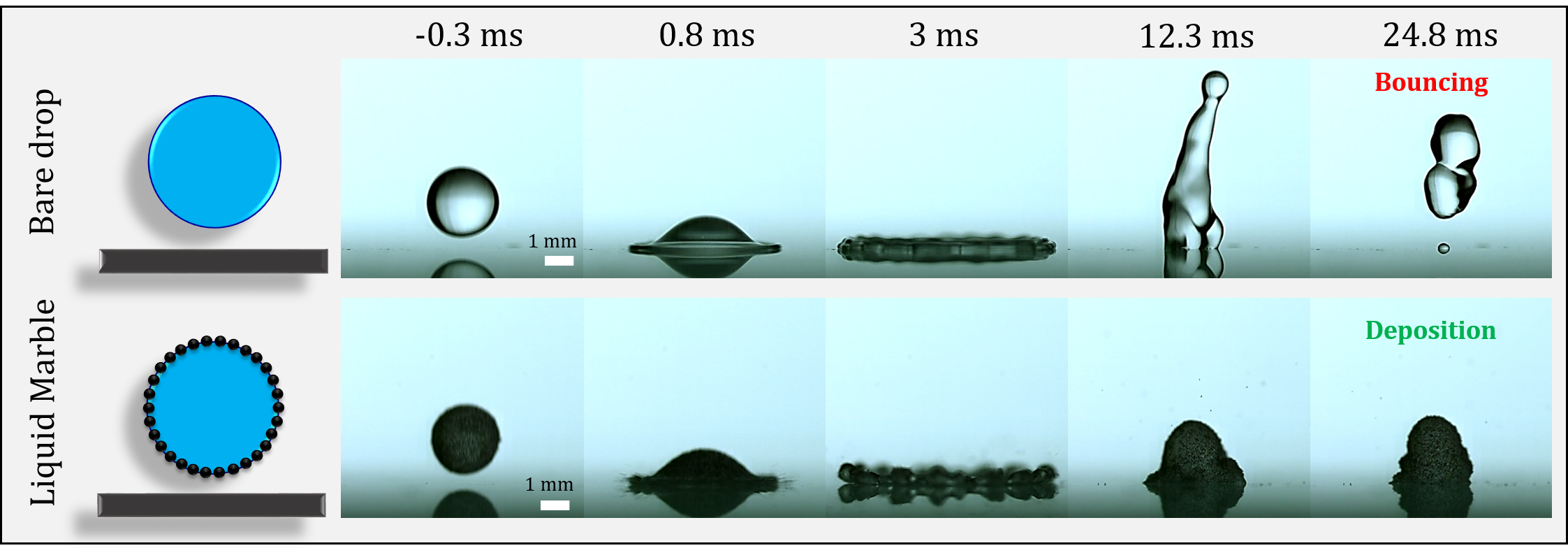

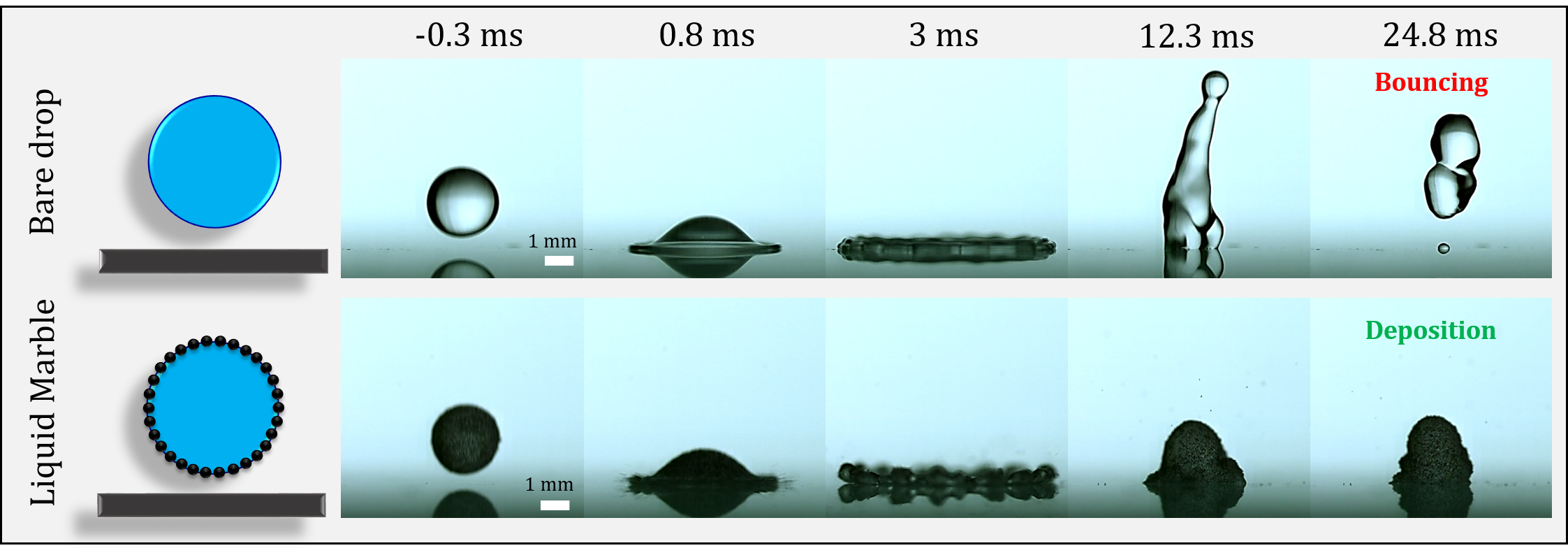

High speed imaging of bare droplet and liquid marble deposition behaviour (Image: Rutvik Lathia)

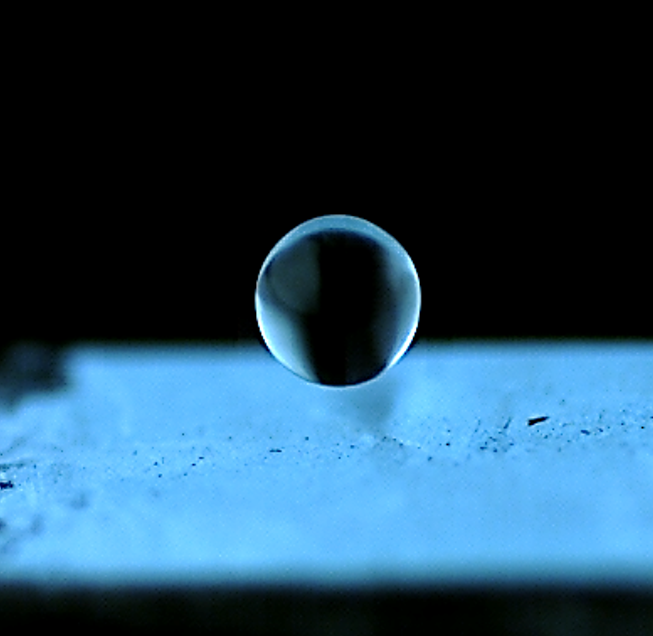

LMs are droplets protected by a coating of hydrophobic particles, and were originally used as miniature vessels for certain chemical and biochemical reactions. The hydrophobic coating protects the tiny volume of liquid inside from external surfaces and air, preventing contamination. However, the IISc team recognised the potential of LMs for droplet deposition because of a previous project that involved droplet impact on superhydrophobic surfaces. They had noticed that the LMs did not bounce off as much as the bare droplets did. This led them to the idea that these LMs could be used for spray or droplet deposition.

Droplet bouncing droplet from a hydrophobic surface (Image: Rutvik Lathia)

To prepare the LMs, the researchers designed a bed of the required hydrophobic particles and allowed water droplets to roll over them freely. To create a hydrophobic surface, the team initially applied a coating of Teflon and PDMS (polydimethylsiloxane) – compounds known for their hydrophobicity and chemical resistance – over a glass and silicon substrate. However, plant surfaces are also flexible in nature. To mimic this, the team fabricated cantilevers using stainless steel of different lengths. A coating of Teflon was then applied to make the surface hydrophobic.

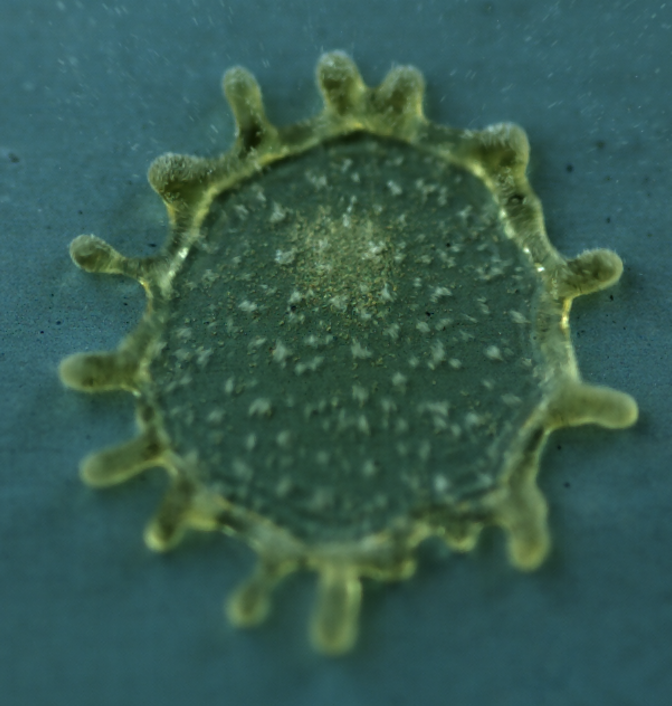

Another challenge was choosing the right hydrophobic particles for the LMs. “The ones used typically in labs have a coating of hydrophobic glass beads and Teflon. But that is very harmful to the plants,” says Lathia. The team, therefore, explored alternative particles that are biodegradable and organic, such as lycopodium and zein. Zein is a protein found in corn, known for its insolubility in water and film-forming properties. LMs made with these materials were found to be more efficient than glass beads-based ones. The team also tested the deposition of these LMs on a rose plant leaf.

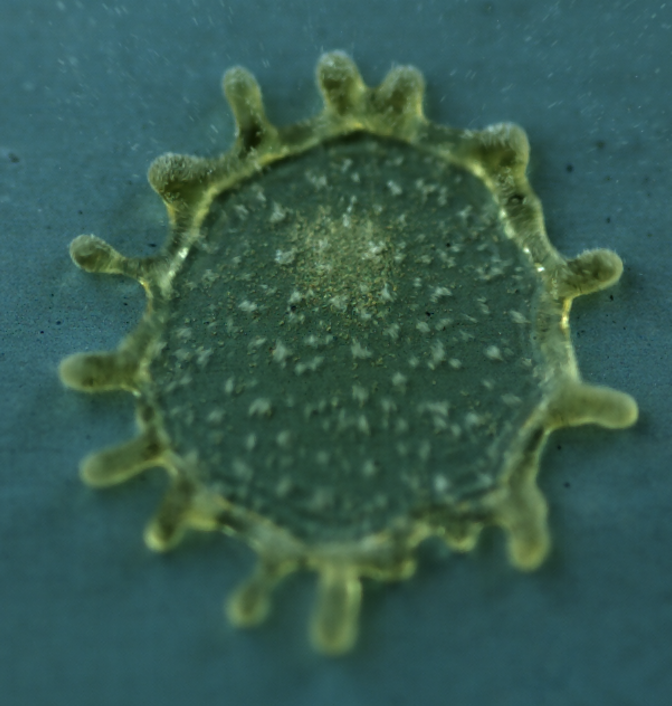

Liquid marble impact on a hydrophobic surface (Image: Rutvik Lathia)

The reason why the LMs are so efficient at deposition, Lathia explains, is that they follow a completely different mode of deposition compared to water droplets.

When an LM strikes a hydrophobic surface, it spreads out, extends in size, and retracts from the surface. This retraction causes the hydrophobic particles to collide with each other, causing a high amount of energy loss due to fluid flow against the jammed particles. Therefore, the droplet inside is unable to regain the kinetic energy to bounce back up, thus sticking to the surface, and boosting droplet deposition.

Liquid marble on a hydrophobic oil-infused surface (Image: Rutvik Lathia)

Besides pesticide deployment, the team is also considering applications in printing on hydrophobic materials such as certain hard plastics.

“With the proof-of-concept done, we have primarily two challenges to tackle,” says Sen. “Firstly, we have to make the method economical. The second is to scale up the process. We need to find a mechanism that creates a large number of LMs when these pesticides are sprayed.”

REFERENCE:

Lathia R, Iyer P, Modak CD, Reddy BS, Sen P, Hydrophobic particle coating for enhanced droplet deposition, Journal of Colloid and Interface Science (2025).

https://linkinghub.elsevier.com/retrieve/pii/S0021979725025366

CONTACT:

Prosenjit Sen

Associate Professor

Centre for Nano Science & Engineering (CeNSE)

Indian Institute of Science (IISc)

Email: prosenjits@iisc.ac.in

Phone: +91-80-22933516

Website: https://sites.google.com/iisc.ac.in/mdhslab/home

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.