A new hope in solid state multicomponent diffusion

Diffusion of components controls physical and mechanical properties of materials at an elevated temperature in many sectors such as aviation, electronics, intermetallic superconductors, energy (nuclear and thermal) etc. However, the understanding of highly complex diffusion processes in multicomponent material systems represents an unsolved area and a challenge to materials engineer due to lack of proper analytical techniques that can deal with the mathematical complexities. The group of Prof. Aloke Paul in the Department of Materials Engineering is pioneering a way forward to address this important issue.

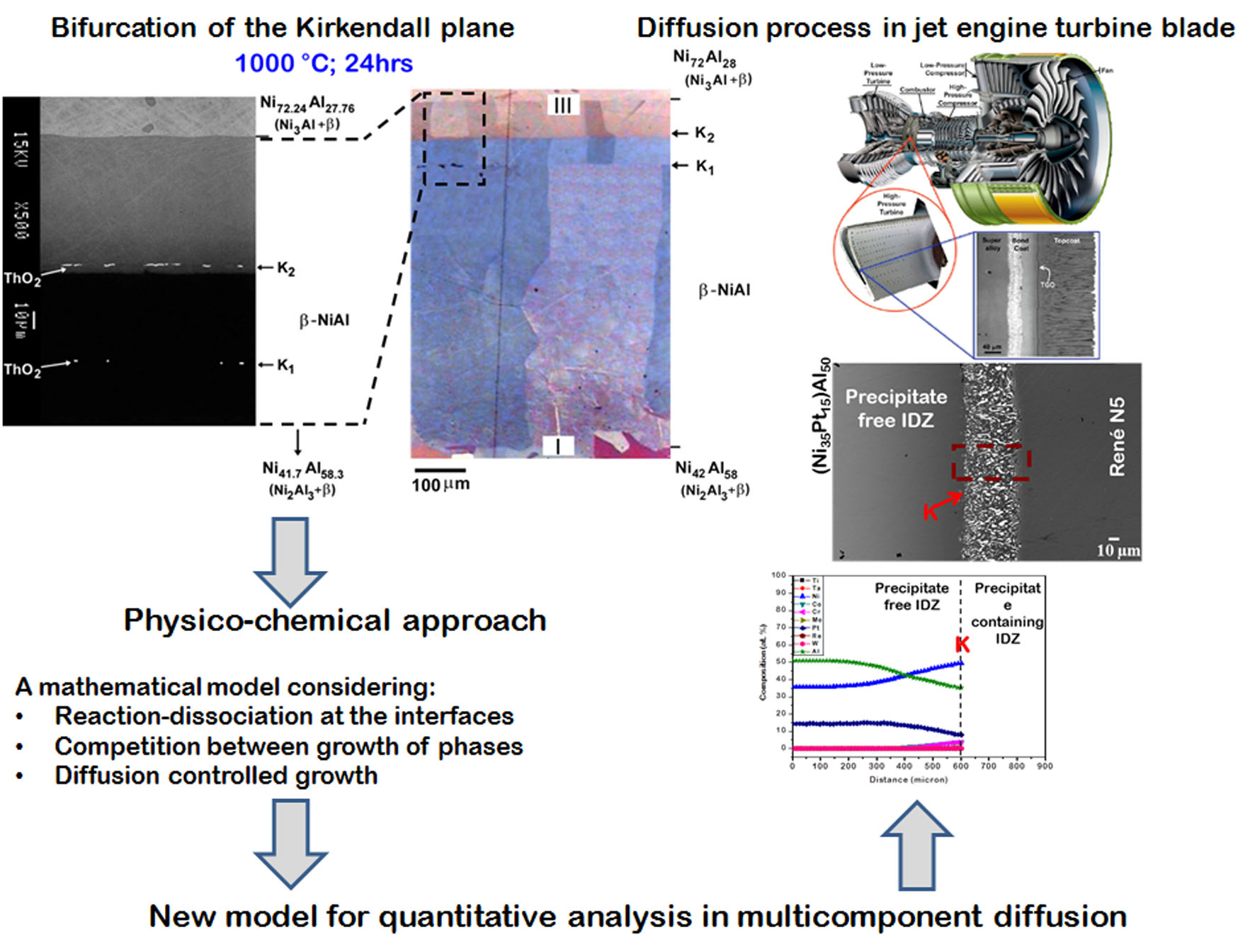

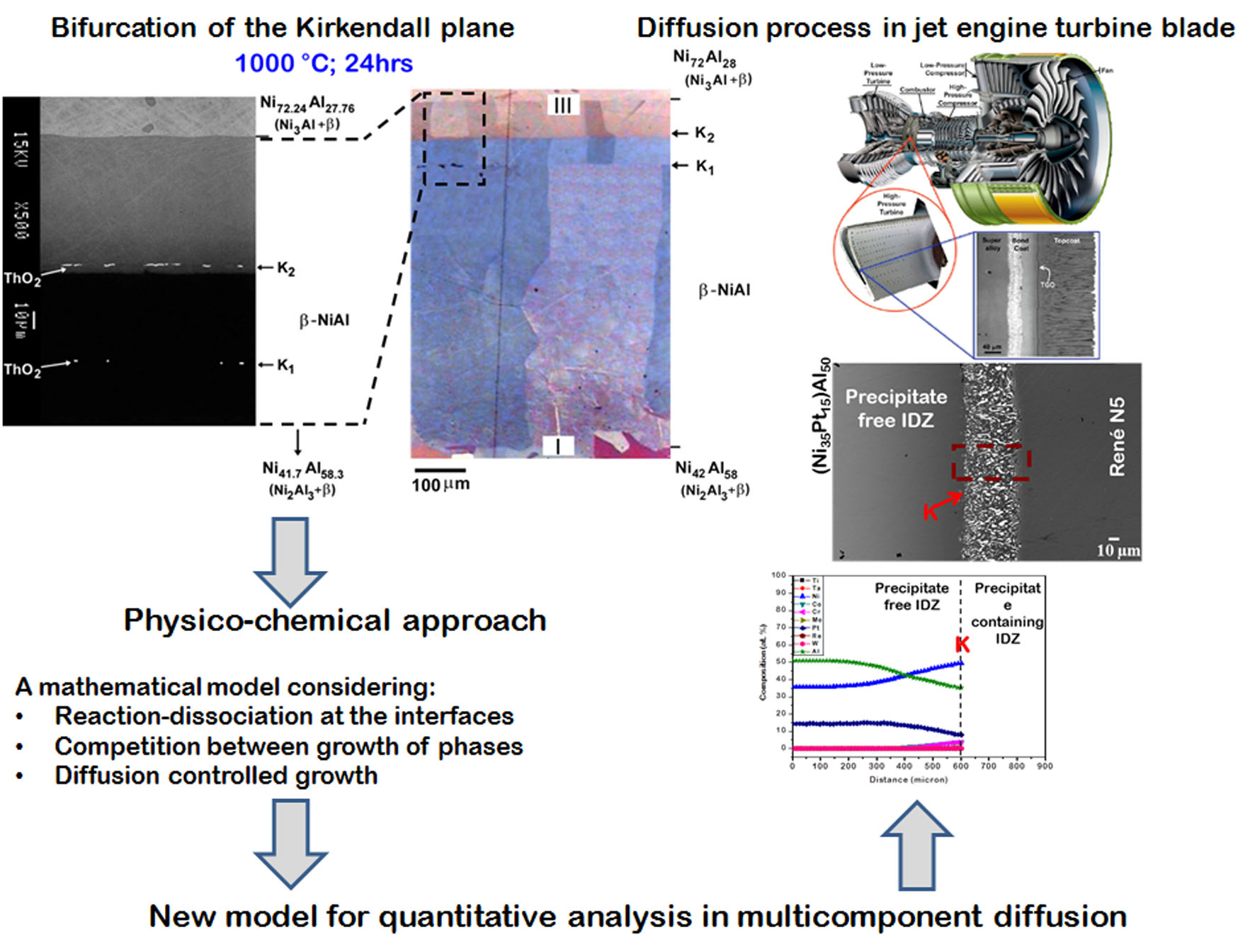

The developments of new theories and analytical methods in his group are initiated based on his Ph.D. thesis work showing an experimental evidence of previously unknown phenomenon related to the Kirkendall effect [1-2]. This is considered as one of the most important discoveries of recent years leading to a much better understanding of the phenomenological diffusion process based on the development of new theoretical models by many groups. One of such examples is the physico-chemical model that is developed by Prof. Paul’s group following which one can quantitatively relate the rate of diffusing components with the evolution of microstructure [3], an important aspect to understand material properties [2].

Presently, Prof. Paul’s group is engaged in developing new models in multicomponent diffusion by tailoring the experiments to counter the mathematical complications of multicomponent systems facilitating the estimation of diffusion coefficients [4-6], which posed a challenging task for a century [2]. In combination with the physico-chemical model, it gives a unique opportunity to relate the thermodynamic driving forces, defects, and microstructure with diffusion rates of components for the explanation of complicated diffusion process, which is demonstrated in material system of turbine blade used in jet engines [7].

The experimental findings and the models developed by Prof. Paul’s group are introduced in classroom teaching in many universities around the world and are being included in new textbooks on this subject [8-10].

References

[1] A. Paul, A.A. Kodentsov and F.J.J. van Loo, Bifurcation of the Kirkendall plane during interdiffusion in the intermetallic compound b-NiAl, Acta Materialia 52 (2004) 4041-4048.

[2] Aloke Paul, Tomi Laurila, Vesa Vuorinen, Sergiy Divinski, Thermodynamics, Diffusion and the Kirkendall effect in Solids, Springer, Germany, 2014.

[3] C. Ghosh and A. Paul, A physico-chemical approach in binary solid-state interdiffusion, Acta Materialia, 55 (2007) 1927-1939.

[4] A. Paul, A pseudobinary approach to study interdiffusion and the Kirkendall effect in multicomponent systems, Philosophical Magazine, 93 (2013) 2297-2315.

[5] S. Santra and A. Paul, Estimation of intrinsic diffusion coefficients in a pseudo-binary diffusion couple, Scripta Materialia 103 (2015) 18-21.

[6] P. Kiruthika and A. Paul, A pseudo-binary interdiffusion study in the β-Ni(Pt)Al phase, Philosophical Magazine Letters 95 (2015) 138-144.

[7] P. Kiruthika, S.K. Makineni, C. Srivastava, K. Chattopadhyay, A. Paul, Growth mechanism of the interdiffusion zone between platinum modified bond coats and single crystal superalloys, Acta Materialia 105 (2016) 438-448.

[8] D. E. Laughlin and K. Hono, Physical Metallurgy (Book), 5th Edition, (former editors: R.W. Cahn and P. Hassen), Chapter 5: Diffusion in Metals and Alloys by Z. Balogh and G. Schmitz, Elsevier, 2014.

[9] G. Grossmann, C. Zardini, The ELFNET book on Failure Mechanisms, Testing Methods and Quality Issues of Lead-free Solder Interconnects (Book), Springer, London, 2012.

[10] H. Mehrer, Diffusion in Solids (Book), Springer, Heidelberg, 2007.

Other Featured research