Texture: the way forward in light metals

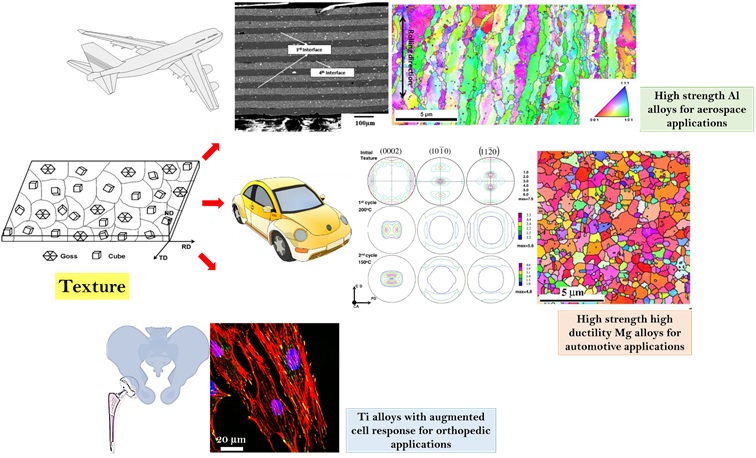

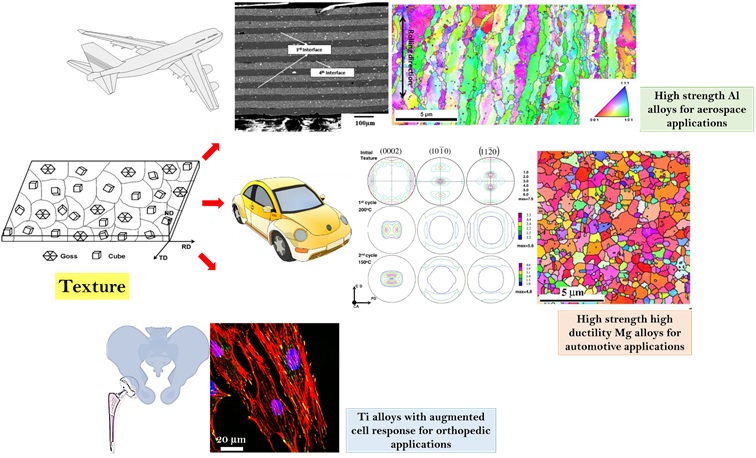

Schematic illustration of the roles of texture in development of materials for applications in aerospace, automotive and biomedical industries

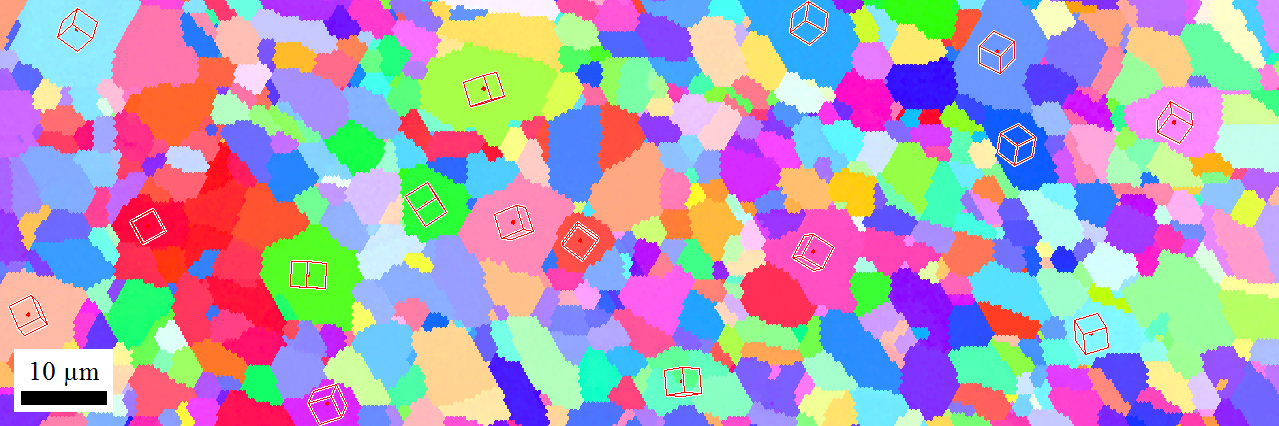

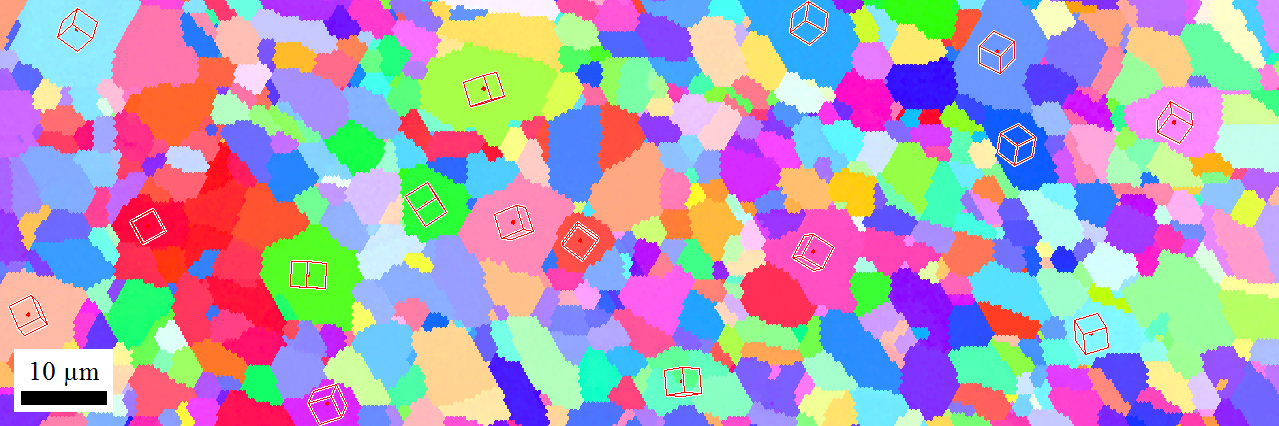

Orientation image map of a recrystallized TWIP steel. Each color represents a specific orientation of the grain. The cubes drawn on some of the grains depict orientations of the cubic crystal in those grains

The word texture brings to minds of many people (scientists or otherwise), the beautiful patterns in objects perceivable by the human eye. However, for Professor Satyam Suwas and his research team, the word texture assumes a more fundamental meaning of a naturally occurring phenomenon in materials, which is not perceived by the human eye and yet is key to engineering materials to support our modern lifestyles. Materials have played such a major role in determining the course of human civilization that they are used to define periods such as the Iron Age and the Bronze Age.

Texture or more precisely crystallographic texture is the field of studying preferred arrangement of crystals within a material. Texture is found to occur in all different classes of materials including metals, ceramic and polymers. The fundamental nature of texture development in the material can be realized by its existence even in the geological materials such as rocks formed over millions of years.

Texture or more precisely crystallographic texture is the field of studying preferred arrangement of crystals within a material. Texture is found to occur in all different classes of materials including metals, ceramic and polymers. The fundamental nature of texture development in the material can be realized by its existence even in the geological materials such as rocks formed over millions of years.

The challenge taken up by Satyam Suwas and his team is to accurately manoeuvre the texture development in light metals and alloys namely magnesium (Mg), titanium (Ti) and aluminium (Al),which find extensive applications in aerospace, automotive and biomedical industries. The lower density of light metals helps in weight reduction and consequently fuel savings in automotive and aerospace industries. The poor ductility of Mg leads to poor formability thereby making components with desired geometry difficult. The lower strength of Al and Mg is also a major barrier in the application of these materials in aerospace and automotive applications. The research group led by Satyam Suwas has developed over the years a gamut of thermo-mechanical processing routes, which essentially involve the application of force and heat to shape materials,to generate textures that significantly improve the properties of these light alloys. One such work is where Mg alloy was processed using an indigenously developed multi-axial forging technique to produce a weak textured material with an ultra-fine grain size. The combination of weak texture and fine grain size in the alloy solved the difficult task of simultaneously achieving high strength and elongation. The ductility of the Mg thus produced was one of the highest ever reported at the time the work was performed. In another work, aerospace grade Al alloy was processed with accumulative roll bonding technique to achieve a 200 % improvement in the yield strength of the alloys. These materials were developed for aircraft wings.

Remarkably, texture affects the performance of these materials when used for biomedical applications such as orthopaedic implants. Ti and Mg are useful for their application in permanent and resorbable implants. Working with his collaborators, Prof. Suwas and his team demonstrated that the load bearing capacity and resistance to degradation can be improved through control of texture. Interestingly, bone cells could sense the texture of the materials through changes in surface energy that affected their growth. These findings open new avenues to engineer the next generation of biomedical materials.

References:

- Madhavan, R., R. Ray, and S. Suwas, Micro-mechanical aspects of texture evolution in nickel and nickel–cobalt alloys: role of stacking fault energy. Philosophical Magazine, 2016. 96(30): p. 3177-3199.

- Biswas, S. and S. Suwas, Evolution of sub-micron grain size and weak texture in magnesium alloy Mg–3Al–0.4 Mn by a modified multi-axial forging process. Scripta Materialia, 2012. 66(2): p. 89-92.

Website URL: http://materials.iisc.ernet.in/~satyamsuwas/

Other Featured research

Texture or more precisely crystallographic texture is the field of studying preferred arrangement of crystals within a material. Texture is found to occur in all different classes of materials including metals, ceramic and polymers. The fundamental nature of texture development in the material can be realized by its existence even in the geological materials such as rocks formed over millions of years.

Texture or more precisely crystallographic texture is the field of studying preferred arrangement of crystals within a material. Texture is found to occur in all different classes of materials including metals, ceramic and polymers. The fundamental nature of texture development in the material can be realized by its existence even in the geological materials such as rocks formed over millions of years.